ifoyile yealuminiyam

Ifoyile ye-aluminiyam licwecwe eliqinileyo le-aluminiyam yealloyi efanelekileyo, iqengqeleke yaya kutsho kubunzima obuncinci kakhulu, obunobunzima obumalunga ne-4.3 ye-microns kunye nobukhulu obukhulu obumalunga ne-150 microns.Ukusuka kwipakethe kunye nezinye iindawo eziphambili zokujonga,

Enye yezona zinto zibalulekileyo zefoyile ye-aluminiyam kukungangeni kwayo kumphunga wamanzi kunye neegesi.Ukufa ii-microns ezingama-25 okanye ngaphezulu azinamanzi ngokupheleleyo.Iigeyiji ezibhityileyo zilayitiwe ukuya kwifilimu edityanisiweyo engagxumekiyo elungele ukupakishwa kunye nokugqunyelelwa ngokubanzi kunye/okanye usetyenziso lomqobo.

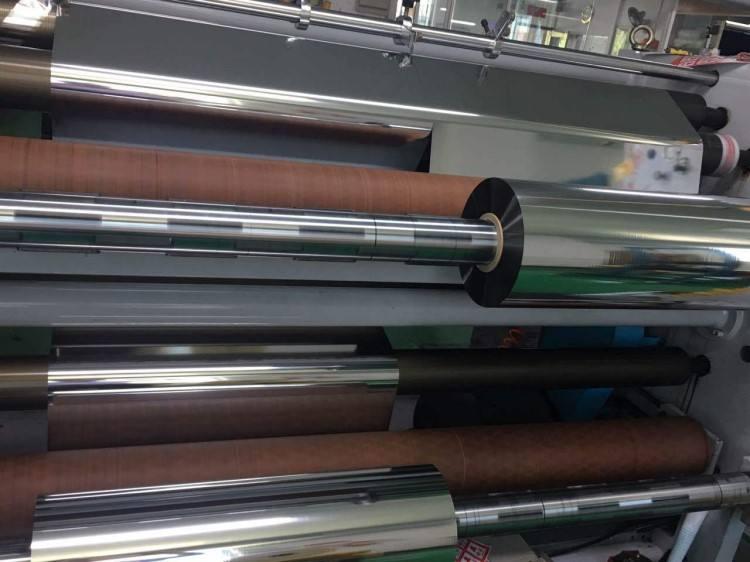

Ifoyile ye-aluminiyam iyafumaneka kwindawo ekhazimlayo kunye neye matt.Ukugqitywa okukhazimlayo kwenziwa xa i-aluminiyam iqengqeleka kwinqanaba lokugqibela.Kunzima ukuvelisa imiqulu enesithuba esincinci esaneleyo sokwenza i-aluminium foil, ngoko ke kwi-lamination yokugqibela, zombini amaphepha asongwe ngaxeshanye, ngokuphindwe kabini ubukhulu ekungeneni komqulu.Kamva xa amagqabi ehlulwe, umphezulu wangaphakathi u-matte kwaye umphandle wangaphandle uyakhazimla.

Ialuminiyam ixhathisa kakhulu kuninzi lwamafutha, ioyile yepetroleum kunye nezinyibilikisi eziphilayo.

Kukho amaqela amathathu ahlukeneyo e-alloys kwimarike, ngalinye lineempawu ezahlukeneyo.Ngoko ke, kubalulekile ukukhetha i-alloy efanelekileyo kakhulu kwisicelo ngasinye sokuphela.

ingxubevange:

- 1235: Kule alloy, umxholo we-aluminium uphezulu kakhulu.I-ductility ye-aluminiyam ecocekileyo ivumela ukuziphatha okuhle kakhulu kwenguqu ngexesha le-lamination, okwenza kube yinto efanelekileyo yokuvelisa iifoyile ezincinci, i-6-9 microns.

Ubuncinci bezinto ezixutywayo zikhokelela kumxholo ophantsi kakhulu wezigaba ze-intermetallic, ngaloo ndlela ukunciphisa inani le-microperforations.

Ukuqina kwezinto eziphathekayo akubalulekanga kolu setyenziso luphela, njengoko iifoyile ezibhityileyo azizange zisetyenziswe ngaphandle kwenkxaso.Oko kukuthi, akuyonxalenye ye-multilayer compound.Amaphepha e-aluminium asebenza njengesithintelo kwisakhiwo, ngelixa iileya zephepha okanye zeplastiki zibonelela

ukumelana noomatshini.

Ukuphela kokusetyenziswa kolu kudibanisa kwegolide kukupakishwa kwe-aseptic liquid,

Iphepha le-cigarette okanye ukupakisha ikofu.

– 8079: Yingxubevange yealuminiyam nentsimbi (Fe).Intsimbi njengento yokudibanisa inyusa amandla efoyile, ekwafuna amandla aphezulu okuguqula ngexesha lokuqengqeleka.Inani elikhulu kunye nobukhulu be-Al-Fe intermetallic compounds, inkulu

Umngcipheko omkhulu we-microperforation.

Ngenxa yoko, iimveliso zentsimbi edibeneyo zisetyenziswa ngokuqhelekileyo kwiimveliso ezinobunzima obukhulu kune-microns eziyi-12 kwaye zilungele ukusetyenziswa okungaqengqelekiyo.Ngakolunye uhlangothi, ngoncedo lwee-intermetallic compounds, isakhiwo sengqolowa yentsimbi enhle kakhulu yenziwe, eyenza imveliso ibe yi-ductile kakhulu kwaye ngaloo ndlela ifezekise ukuphakama okuphezulu kunye nokuqhuma kwamandla amaxabiso.

Le propati iyimfuneko kwizicelo apho isakhiwo sisongwe ngamaxesha amaninzi kwaye iphepha le-aluminium kufuneka libe ne-elongation eyaneleyo yokukhubazeka kwindawo yokugoba ngaphandle kokuphulwa.

Eyona nto imele isetyenziswe ekugqibeleni iipakethi ze-blister ezibandayo, iibhotile zebhotile kunye ne-wrappers yetshokolethi.

– 8011: Yingxubevange ye-aluminiyam-iron-manganese.Ukongezwa kwemanganese kwandisa amandla efoyile ye-aluminium.Iialloys zeFerromanganese zifanelekile apho kufuneka amandla aphezulu kakhulu.

Iialloys ze-Al-Fe-Mn ziqhele ukusetyenziswa kwiimveliso apho ukuncitshiswa kwe-elongation kungabalulekanga, kodwa amandla abalulekile kwi-compound okanye kuyimfuneko kwinkqubo yokuguqulwa.

I-aluminium foil isetyenziswa ngokubanzi kwipakethe yokutya kunye namayeza ngenxa yokuba ivala ngokupheleleyo ukukhanya kunye ne-oksijini (ebangela i-oxidation yamafutha okanye i-rancidity), ivumba kunye nencasa, ukufuma kunye neebhaktheriya.I-aluminium foil isetyenziselwa ukwenza i-long-life packaging (i-aseptic packaging) yeziselo kunye neemveliso zobisi ezinokugcinwa ngaphandle kwefriji.

I-foil laminates zikwasetyenziselwa ukupakisha ukutya okuninzi okungevani neoksijini okanye ukufuma, icuba, ngohlobo lweengxowa, imvulophu, kunye neetyhubhu, kunye nokuvalwa okunganyangekiyo.

Izikhongozeli zefoyile kunye neetreyi zisetyenziselwa ukubhaka izinto ezibhakiweyo kunye neepakethe ezithathwayo, izinto ezilungele ukutyiwa kunye nokutya kwesilwanyana sasekhaya.

I-aluminium foil iphinda isetyenziswe ngokubanzi kwi-thermal insulation (i-barrier kunye ne-reflection), i-heat exchangers (i-thermal conduction) kunye ne-cable jacketing (umqobo wayo kunye nokuhamba kombane).

– Isingxobo esiguquguqukayo ngokubanzi

-Izikhongozeli eziPasteurizable (ibuyisela)

– kwizikhongozeli zodidi lweTetra

– kunye nokugquma kwetywina lobushushu

- kunye ne-self-adhesive coating

– indlu

– iiCapacitors

-Intambo yevidiyo

- Igolide okanye eminye imibala

– Iqatywe amadyungudyungu amayeza

– Ukuhombisa

– kunye PE ukutyabeka

– ngeenkozo zetshokolethi

– Igutyungelwe

– kunye non-stick ukutyabeka

– Iqatywe ukupakishwa kwesonka samasi

– Iikepusi zebhotile yebhiya –

ityhubhu yentlama yamazinyo

– kubatshintshi bobushushu

Ifoyile yeAluminiyam iza kwiifomathi ezahlukeneyo:

Iialloyi ezifumanekayo:

– 1235

– 8011

– 8079

-Ukutyeba: Ubungqingqwa bentengiso obuqhelekileyo ziimicrons ezi-6 ukuya kuma-80 eemicrons.Ezinye izalathisi kufuneka zibhekiswe.

- Iitempile ezahlukeneyo, ezisetyenziswa ngokuqhelekileyo ziyi-H-0 (ethambileyo) kunye ne-H-18 (inzima).

-Isicelo: Iishiti zezicelo ezithile, ezinjengezikhongozeli ezibuyiselwayo, izikhongozeli zamayeza, njl.njl., zifuna ukucaciswa okukhethekileyo kwe-microporous.

– Ukumanzisa: Udidi A

– Sebenzisa uhlobo olwahlukileyo lokugquma ukuba kuyimfuneko.Ingatywinwa ubushushu, inemibala, iprintwe, ifakwe i-embossed, i-corrugated, njl.

Ixesha lokuposa: Nov-22-2022